摆碾铆机

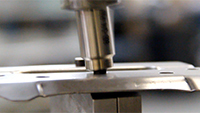

Orbitform’s standard modular bench and pedestal machines offer a range of complete turn-key assembly solution for orbital riveting and forming for work pieces 0.125” dia. to over 1 inch (3.1 mm to 25 mm) for a consistent form.

- 型号

- P-500

- P-750

- P-840

- P-1000

- P-1500

- H-1000

Orbitform’s P-500 pedestal machine is designed for medium to large size work piece orbital riveting and radial riveting. The pedestal machine, comprised of an orbital forming modular powerhead, orbital head with developed peen, fabricated pedestal, work support saddle with t-slots for easy fixture mounting, and complete controls, is commonly used with riveting machines that assemble door and hood hinges, seat track structures, striker assemblies, furniture sub-assemblies, various automotive components, and other medium to large scale riveted assemblies. Orbitform’s application engineers outline the required orbital head and orbital peen to conduct the riveting application and, if the customer desires, Orbitform can design and build custom machine actuation, a safety system, a fixturing method, an error proofing process, and/or other expert assembly features associated with orbital riveting machines and automatic assembly equipment.

| Weight | 850 lbs |

| Throat Depth | 9.0" (28.5mm) |

| Head Forming Capacity | .500" (12.75mm) |

| Max Downward Force | 4400 lbs @ 100 psi |

| Max Stroke | 2.5" (63.5mm) |

- Download .dwg

- Download .easm

- Download .step

Orbitform’s modular P-500 pedestal machine is manufactured and assembled at Orbitform’s factory in Jackson, Michigan, USA. The orbital riveting pedestal machine is available with many standard features and the orbital forming pedestal machine can be customized with options to help monitor, control, and improve the assembly process. Orbitform’s application engineers listen and seek the appropriate answer for each specific assembly process being considered. Orbitform can design and build a complete turnkey assembly system including controls, safety, fixtures, errorproofing, and more.

Extended stroke requirements?

Applications with similar orbital riveting or orbital forming force but requiring extended vertical clearance for part loading may benefit from the extended stroke Orbitform pedestal machine model P-506.

- The P-506 Orbitform pedestal machine has a total tool stroke distance of 6 in (152 mm) that is adjustable between 3 in to 6 in (76 mm to 152 mm).

Standard Features and Specifications for Orbital Riveting or Orbital Forming Applications:

- Powerhead with electric motor and orbital head with peen developed and tested for each application

- Fabricated Pedestal and work support Saddle w/10" [254 mm] vertical height adjustment

- HMI touch panel for enhanced diagnostics

- Directional valve with dual pilot operated (PO) check to prevent powerhead drifting

- Dual low actuation force palm buttons for cycling the machine

- Pneumatic solenoid valves to assist with smooth and exact fluid motion

- Filter-regulator unit with gauge to keep the air supply clean and protect the machine’s components

- Digital adjustable dwell timer

- Resettable cycle counter to keep track of machine cycles

- Electrical enclosure with disconnect switch

- Illuminated power on selector switch

- Programmable Logic Controller

- Internally mounted home, deceleration and full stroke limit switches

- Programmable Logic Controller

Bench Machine Options:

Electrical Options

- Light curtains for operator safety

- PLC expansion for an additional I/O

- Low-profile LED worklight to enhance the lighting of the work area

Mechanical Options

- Guarding for operator safety

- Air line lubricator

- Custom part fixturing designed and built by Orbitform allowing a turnkey riveting solution

- Pneumatic fixture slide to allow for simpler part loading

- Offset motor mount to allow for a shorter machine height and/or to allow for a through spindle pressure pad

- Gear reducer to reduce the RPM to allow for the optimal forming speed

- Spindle brake to control the tool position or to stop the tool rotation for certain applications

- Anti-rotate device to prevent the peen from rotating during certain assembly or forming applications

- Orbital alignment kit to help you set up the machine if the machine configurations change

Error Proofing, Process Monitoring, Process Control Options

- Process Intelligence Package: Load Cell, LVDT (Linear Variable Displacement Transducer), Touch Screen

- Pressure pad (standard, height sensing, or programmable height sensing) to secure the work piece prior to forming or assembly, to assist with assembly process monitoring / process control, or to confirm part presence prior to continuing the assembly process

Forming Options

- Radial head for radial riveting (radial riveting) or radial forming assembly (radial forming assembly) applications when the radial forming process is preferred

- Multi-point or Multi-spindle head for orbital riveting or orbital forming of multiple rivets at the same time

- Static rollerhead for roller forming or roller assembly applications

- Articulating rollerhead for roller forming or roller assembly applications

- Press head powerhead configuration and press tooling to allow the powerhead to act as a press for pressing parts together into any assembly

Orbitform’s P-750 pedestal machine is designed for medium to large size work piece orbital riveting and radial riveting. The pedestal machine, comprised of an orbital forming modular powerhead, orbital head with developed peen, fabricated pedestal, work support saddle with t-slots for easy fixture mounting, and complete controls, is commonly used to assemble robust hinges, large brackets, brake components, industrial hand tools, automotive foot pedals, ball stud assemblies, and other medium to large scale riveted assemblies. Orbitform’s application engineers outline the required orbital head and orbital peen to conduct the riveting application and, if the customer desires, Orbitform can design and build custom machine actuation, a safety system, a fixturing method, an error proofing process, and/or other expert assembly features associated with orbital riveting machines and automatic assembly equipment.

| Weight | 950 lbs |

| Throat Depth | 9.0" (28.5mm) |

| Head Forming Capacity | .750" (8mm) |

| Max Downward Force | 7510 lbs @ 100 psi |

| Max Stroke | 2.5" (63.5mm) |

- Download .dwg

- Download .easm

- Download .step

Orbitform’s modular P-750 pedestal machine is manufactured and assembled at Orbitform’s factory in Jackson, Michigan, USA. The orbital riveting pedestal machine is available with many standard features and the orbital forming pedestal machine can be customized with options to help monitor, control, and improve the assembly process. Orbitform’s application engineers listen and seek the appropriate answer for each specific assembly process being considered. Orbitform can design and build a complete turnkey assembly system including controls, safety, fixtures, errorproofing, and more.

Standard Features and Specifications for Orbital Riveting or Orbital Forming Applications:

- Powerhead with electric motor and orbital head with peen developed and tested for each application

- Fabricated Pedestal and work support Saddle w/10" [254 mm] vertical height adjustment

- HMI touch panel for enhanced diagnostics

- Directional valve with dual pilot operated (PO) check to prevent powerhead drifting

- Dual low actuation force palm buttons for cycling the machine

- Pneumatic solenoid valves to assist with smooth and exact fluid motion

- Filter-regulator unit with gauge to keep the air supply clean and protect the machine’s components

- Digital adjustable dwell timer

- Resettable cycle counter to keep track of machine cycles

- Electrical enclosure with disconnect switch

- Illuminated power on selector switch

- Programmable Logic Controller

- Internally mounted home, deceleration and full stroke limit switches

- Programmable Logic Controller

Bench Machine Options:

Electrical Options

- Light curtains for operator safety

- PLC expansion for an additional I/O

- Low-profile LED worklight to enhance the lighting of the work area

Mechanical Options

- Guarding for operator safety

- Air line lubricator

- Custom part fixturing designed and built by Orbitform allowing a turnkey riveting solution

- Pneumatic fixture slide to allow for simpler part loading

- Offset motor mount to allow for a shorter machine height and/or to allow for a through spindle pressure pad

- Gear reducer to reduce the RPM to allow for the optimal forming speed

- Spindle brake to control the tool position or to stop the tool rotation for certain applications

- Anti-rotate device to prevent the peen from rotating during certain assembly or forming applications

- Orbital alignment kit to help you set up the machine if the machine configurations change

Error Proofing, Process Monitoring, Process Control Options

- Process Intelligence Package: Load Cell, LVDT (Linear Variable Displacement Transducer), Touch Screen

- Pressure pad (standard, height sensing, or programmable height sensing) to secure the work piece prior to forming or assembly, to assist with assembly process monitoring / process control, or to confirm part presence prior to continuing the assembly process

Forming Options

- Radial head for radial riveting (radial riveting) or radial forming assembly (radial forming assembly) applications when the radial forming process is preferred

- Multi-point or Multi-spindle head for orbital riveting or orbital forming of multiple rivets at the same time

- Static rollerhead for roller forming or roller assembly applications

- Articulating rollerhead for roller forming or roller assembly applications

- Press head powerhead configuration and press tooling to allow the powerhead to act as a press for pressing parts together into any assembly

Orbitform’s P-840 pedestal machine is the highest capacity pneumatic orbital forming and orbital riveting pedestal machine available in the world. The Orbitform pedestal machine is perfectly suited for large size work piece orbital riveting processes and orbital cold forming assembly processes. The pedestal machine, comprised of an orbital forming modular powerhead, orbital head with developed peen, fabricated pedestal, work support saddle with t-slots for easy fixture mounting, and complete controls, is commonly used to form spindle shafts, and assemble large automotive hinges, robust brake components, seat track products, and other large scale riveted assemblies. Orbitform’s application engineers outline the required orbital head and orbital peen to conduct the riveting application and, if the customer desires, Orbitform can design and build custom machine actuation, a safety system, a fixturing method, an error proofing process, and/or other expert assembly features associated with orbital riveting machines and automatic assembly equipment.

| Weight | 1200 lbs |

| Throat Depth | 9.0" (28.5mm) |

| Head Forming Capacity | .840" (21.25mm) |

| Max Downward Force | 12,500 lbs @ 100 psi |

| Max Stroke | 2.5" (63.5mm) |

- Download .dwg

- Download .eprt

- Download .step

Orbitform’s modular P-840 pedestal machine is manufactured and assembled at Orbitform’s factory in Jackson, Michigan, USA. The orbital riveting pedestal machine is available with many standard features and the orbital forming pedestal machine can be customized with options to help monitor, control, and improve the assembly process. Orbitform’s application engineers listen and seek the appropriate answer for each specific assembly process being considered. Orbitform can design and build a complete turnkey assembly system including controls, safety, fixtures, errorproofing, and more.

Standard Features and Specifications for Orbital Riveting or Orbital Forming Applications:

- Powerhead with electric motor and orbital head with peen developed and tested for each application

- Fabricated Pedestal and work support Saddle w/10" [254 mm] vertical height adjustment

- HMI touch panel for enhanced diagnostics

- Directional valve with dual pilot operated (PO) check to prevent powerhead drifting

- Dual low actuation force palm buttons for cycling the machine

- Pneumatic solenoid valves to assist with smooth and exact fluid motion

- Filter-regulator unit with gauge to keep the air supply clean and protect the machine’s components

- Digital adjustable dwell timer

- Resettable cycle counter to keep track of machine cycles

- Electrical enclosure with disconnect switch

- Illuminated power on selector switch

- Programmable Logic Controller

- Internally mounted home, deceleration and full stroke limit switches

- Programmable Logic Controller

Bench Machine Options:

Electrical Options

- Light curtains for operator safety

- PLC expansion for an additional I/O

- Low-profile LED worklight to enhance the lighting of the work area

Mechanical Options

- Guarding for operator safety

- Air line lubricator

- Custom part fixturing designed and built by Orbitform allowing a turnkey riveting solution

- Pneumatic fixture slide to allow for simpler part loading

- Offset motor mount to allow for a shorter machine height and/or to allow for a through spindle pressure pad

- Gear reducer to reduce the RPM to allow for the optimal forming speed

- Spindle brake to control the tool position or to stop the tool rotation for certain applications

- Anti-rotate device to prevent the peen from rotating during certain assembly or forming applications

- Orbital alignment kit to help you set up the machine if the machine configurations change

Error Proofing, Process Monitoring, Process Control Options

- Process Intelligence Package: Load Cell, LVDT (Linear Variable Displacement Transducer), Touch Screen

- Pressure pad (standard, height sensing, or programmable height sensing) to secure the work piece prior to forming or assembly, to assist with assembly process monitoring / process control, or to confirm part presence prior to continuing the assembly process

Forming Options

- Multi-point or Multi-spindle head for orbital riveting or orbital forming of multiple rivets at the same time

- Static rollerhead for roller forming or roller assembly applications

- Articulating rollerhead for roller forming or roller assembly applications

- Press head powerhead configuration and press tooling to allow the powerhead to act as a press for pressing parts together into any assembly

Orbitform’s P-1000 hydraulic powered pedestal machine is perfectly suited for large size work piece orbital riveting processes and orbital cold forming assembly processes. The pedestal machine, comprised of an orbital forming modular powerhead, orbital head with developed peen, fabricated pedestal, work support saddle with t-slots for easy fixture mounting, and complete controls, is commonly used to form spindle shafts, and assemble large automotive hinges, robust brake components, seat track products, and other large scale riveted assemblies. Orbitform’s application engineers outline the required orbital head and orbital peen to conduct the riveting application and, if the customer desires, Orbitform can design and build custom machine actuation, a safety system, a fixturing method, an error proofing process, and/or other expert assembly features associated with orbital riveting machines and automatic assembly equipment.

| Weight | 1150 lbs |

| Throat Depth | 9.0" (28.5mm) |

| Head Forming Capacity | 1.0" (25.5mm) |

| Max Downward Force | 18,000 lbs @ 1000 psi |

| Max Stroke | 2.5" (63.5mm) |

- Download .dwg

- Download .easm

- Download .step

Orbitform’s modular P-1000 pedestal machine is manufactured and assembled at Orbitform’s factory in Jackson, Michigan, USA. The orbital riveting pedestal machine is available with many standard features and the orbital forming pedestal machine can be customized with options to help monitor, control, and improve the assembly process. Orbitform’s application engineers listen and seek the appropriate answer for each specific assembly process being considered. Orbitform can design and build a complete turnkey assembly system including controls, safety, fixtures, errorproofing, and more

Extended stroke requirements?

Applications with similar orbital riveting or orbital forming force but requiring extended vertical clearance for part loading may benefit from the extended stroke Orbitform hydraulic pedestal machine model M-1006.

- The P-1006 Orbitform pedestal machine has a total tool stroke distance of 6 in (152 mm) that is adjustable between 3 in to 6 in (76 mm to 152 mm)

Standard Features and Specifications for Orbital Riveting or Orbital Forming Applications:

- Powerhead with electric motor and orbital head with peen developed and tested for each application

- Fabricated Pedestal and work support Saddle w/10" [254 mm] vertical height adjustment

- HMI touch panel for enhanced diagnostics

- Directional valve with dual pilot operated (PO) check to prevent powerhead drifting

- Dual low actuation force palm buttons for cycling the machine

- Pneumatic solenoid valves to assist with smooth and exact fluid motion

- Filter-regulator unit with gauge to keep the air supply clean and protect the machine’s components

- Digital adjustable dwell timer

- Resettable cycle counter to keep track of machine cycles

- Electrical enclosure with disconnect switch

- Illuminated power on selector switch

- Programmable Logic Controller

- Internally mounted home, deceleration and full stroke limit switches

- Programmable Logic Controller

Bench Machine Options:

Electrical Options

- Light curtains for operator safety

- PLC expansion for an additional I/O

- Low-profile LED worklight to enhance the lighting of the work area

Mechanical Options

- Guarding for operator safety

- Air line lubricator

- Custom part fixturing designed and built by Orbitform allowing a turnkey riveting solution

- Pneumatic fixture slide to allow for simpler part loading

- Offset motor mount to allow for a shorter machine height and/or to allow for a through spindle pressure pad

- Gear reducer to reduce the RPM to allow for the optimal forming speed

- Spindle brake to control the tool position or to stop the tool rotation for certain applications

- Anti-rotate device to prevent the peen from rotating during certain assembly or forming applications

- Orbital alignment kit to help you set up the machine if the machine configurations change

Error Proofing, Process Monitoring, Process Control Options

- Process Intelligence Package: Load Cell, LVDT (Linear Variable Displacement Transducer), Touch Screen

- Pressure pad (standard, height sensing, or programmable height sensing) to secure the work piece prior to forming or assembly, to assist with assembly process monitoring / process control, or to confirm part presence prior to continuing the assembly process

Forming Options

- Multi-point or Multi-spindle head for orbital riveting or orbital forming of multiple rivets at the same time

- Static rollerhead for roller forming or roller assembly applications

- Articulating rollerhead for roller forming or roller assembly applications

- Press head powerhead configuration and press tooling to allow the powerhead to act as a press for pressing parts together into any assembly

Orbitform’s P-1500 hydraulic powered pedestal machine is perfectly suited for large size work piece orbital riveting processes and orbital cold forming assembly processes. The pedestal machine, comprised of an orbital forming modular powerhead, orbital head with developed peen, fabricated pedestal, work support saddle with t-slots for easy fixture mounting, and complete controls, is commonly used to form spindle shafts, and assemble large automotive hinges, robust brake components, seat track products, and other large scale riveted assemblies. Orbitform’s application engineers outline the required orbital head and orbital peen to conduct the riveting application and, if the customer desires, Orbitform can design and build custom machine actuation, a safety system, a fixturing method, an error proofing process, and/or other expert assembly features associated with orbital riveting machines and automatic assembly equipment.

| Weight | 1500 lbs |

| Throat Depth | 10.0" (254mm) |

| Head Forming Capacity | 1.5" (38mm) |

| Max Downward Force | 38,500 lbs @ 1000 psi |

| Max Stroke | 3.0" (76.25mm) |

- Download .dwg

- Download .easm

- Download .step

Orbitform’s modular P-1500 pedestal machine is manufactured and assembled at Orbitform’s factory in Jackson, Michigan, USA. The orbital riveting pedestal machine is available with many standard features and the orbital forming pedestal machine can be customized with options to help monitor, control, and improve the assembly process. Orbitform’s application engineers listen and seek the appropriate answer for each specific assembly process being considered. Orbitform can design and build a complete turnkey assembly system including controls, safety, fixtures, errorproofing, and more.

Standard Features and Specifications for Orbital Riveting or Orbital Forming Applications:

- Powerhead with electric motor and orbital head with peen developed and tested for each application

- Fabricated Pedestal and work support Saddle w/10" [254 mm] vertical height adjustment

- HMI touch panel for enhanced diagnostics

- Directional valve with dual pilot operated (PO) check to prevent powerhead drifting

- Dual low actuation force palm buttons for cycling the machine

- Pneumatic solenoid valves to assist with smooth and exact fluid motion

- Filter-regulator unit with gauge to keep the air supply clean and protect the machine’s components

- Digital adjustable dwell timer

- Resettable cycle counter to keep track of machine cycles

- Electrical enclosure with disconnect switch

- Illuminated power on selector switch

- Programmable Logic Controller

- Internally mounted home, deceleration and full stroke limit switches

- Programmable Logic Controller

Bench Machine Options:

Electrical Options

- Light curtains for operator safety

- PLC expansion for an additional I/O

- Low-profile LED worklight to enhance the lighting of the work area

Mechanical Options

- Guarding for operator safety

- Air line lubricator

- Custom part fixturing designed and built by Orbitform allowing a turnkey riveting solution

- Pneumatic fixture slide to allow for simpler part loading

- Offset motor mount to allow for a shorter machine height and/or to allow for a through spindle pressure pad

- Gear reducer to reduce the RPM to allow for the optimal forming speed

- Spindle brake to control the tool position or to stop the tool rotation for certain applications

- Anti-rotate device to prevent the peen from rotating during certain assembly or forming applications

- Orbital alignment kit to help you set up the machine if the machine configurations change

Error Proofing, Process Monitoring, Process Control Options

- Process Intelligence Package: Load Cell, LVDT (Linear Variable Displacement Transducer), Touch Screen

- Pressure pad (standard, height sensing, or programmable height sensing) to secure the work piece prior to forming or assembly, to assist with assembly process monitoring / process control, or to confirm part presence prior to continuing the assembly process

Forming Options

- Multi-point or Multi-spindle head for orbital riveting or orbital forming of multiple rivets at the same time

- Static rollerhead for roller forming or roller assembly applications

- Articulating rollerhead for roller forming or roller assembly applications

- Press head powerhead configuration and press tooling to allow the powerhead to act as a press for pressing parts together into any assembly

Orbitform’s H-1000 hydraulic powered H-Frame machine is perfectly suited for large size work piece orbital riveting processes and orbital cold forming assembly processes. The H-Frame and reinforced work stand provided superior stability under high-forming forces for precise repeatable forming. The system is comprised of an orbital forming modular hydraulic powerhead, fabricated reinforced bench and H-Frame support, orbital head with developed peen, and complete controls, is commonly used to form spindle shafts, and assemble large automotive hinges, robust brake components, seat track products, and other large scale riveted assemblies. Orbitform’s application engineers outline the required orbital head and orbital peen to conduct the riveting application and, if the customer desires, Orbitform can design and build custom machine actuation, a safety system, a fixturing method, an error proofing process, and/or other expert assembly features associated with orbital riveting machines and automatic assembly equipment.

| Throat Depth | n/a |

| Head Forming Capacity | 1.0" (25.5mm) |

| Max Downward Force | 18,000 lbs @ 1000 psi |

| Max Stroke | 2.5" (63.5mm) |

- Download .dwg

- Download .eprt

- Download .step

Orbitform’s modular H-1000 pedestal machine is manufactured and assembled at Orbitform’s factory in Jackson, Michigan, USA. The orbital riveting pedestal machine is available with many standard features and the orbital forming pedestal machine can be customized with options to help monitor, control, and improve the assembly process. Orbitform’s application engineers listen and seek the appropriate answer for each specific assembly process being considered. Orbitform can design and build a complete turnkey assembly system including controls, safety, fixtures, and error-proofing to any specification.

Standard Features and Specifications for Orbital Riveting or Orbital Forming Applications:

- Powerhead with electric motor and orbital head with peen developed and tested for each application

- Fabricated reinforced work stand and H-Frame with precision bearing housings

- The unit is fixtured to the needed height

- HMI touch panel for enhanced diagnostics

- Directional valve with dual pilot operated (PO) check to prevent powerhead drifting

- Dual low actuation force palm buttons for cycling the machine

- Pneumatic solenoid valves to assist with smooth and exact fluid motion

- Digital adjustable dwell timer

- Re-settable cycle counter to keep track of machine cycles

- Electrical enclosure with disconnect switch

- Illuminated power on selector switch

- Programmable Logic Controller

- Internally mounted home, deceleration and full stroke limit switches

- Programmable Logic Controller

H-Frame Machine Options:

Electrical Options

- Light curtains for operator safety

- PLC expansion for an additional I/O

- Low-profile LED work-light to enhance the lighting of the work area

Mechanical Options

- Guarding for operator safety

- Air line lubricator

- Custom part fixturing designed and built by Orbitform allowing a turnkey riveting solution

- Pneumatic fixture slide to allow for simpler part loading

- Offset motor mount to allow for a shorter machine height and/or to allow for a through spindle pressure pad

- Gear reducer to reduce the RPM to allow for the optimal forming speed

- Spindle brake to control the tool position or to stop the tool rotation for certain applications

- Anti-rotate device to prevent the peen from rotating during certain assembly or forming applications

- Orbital alignment kit to help you set up the machine if the machine configurations change

Error Proofing, Process Monitoring, Process Control Options

- Process Intelligence Package: Load Cell, LVDT (Linear Variable Displacement Transducer), Touch Screen

- Pressure pad (standard, height sensing, or programmable height sensing) to secure the work piece prior to forming or assembly, to assist with assembly process monitoring / process control, or to confirm part presence prior to continuing the assembly process

Forming Options

- Multi-point or Multi-spindle head for orbital riveting or orbital forming of multiple rivets at the same time

- Static rollerhead for roller forming or roller assembly applications

- Articulating rollerhead for roller forming or roller assembly applications

- Press head powerhead configuration and press tooling to allow the powerhead to act as a press for pressing parts together into any assembly